The reason I made this site? Well, there are a few things I think

may be interesting for some people out there. By no means I think

this will be the

ultimate ETX-page, but I just want to put some stuff on my own

site. That's why I got this domain anyway...

First, a bit of history. When I was young (about 13) I met a guy in school, who took me to a society of young amateur-astronomers, the JWG. I became hooked, and with the help of my father, we build our own telescope, a 15cm (~6") newton. Unfortunate, due to our inexperience, we didn't use it very much. Part because we lived in a urban area, part because the computer (VIC-20!) began to take our interest.

So did my 'dark years' start (or should I say 'light years'?). My interest in astronomy stayed, but was limited to the news I saw on the TV, or looking up on a starry night, impressing my friends about my knowledge.

Until March 1999. My wife and I went on a small holiday to Tunesia. At the airport, I bought a few magazines to read while lying by the pool. One of the magazines was a 'Sky & Telescope'. An old passion reared its head again....

To make a long story short, I bought a Meade

ETX 125/ec with the AutoStar controller. I chose this telescope

because of the portability, value-for-price and (important) the

GOTO-functionality. I know, it's not very sporty, but hey, it's my

scope.... 8-)

The information provided here is (yet) rather limited. I hope I

will be able to put on some more info, but I hope this will be

enough at the moment.

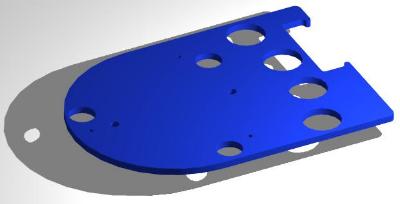

This

is the mounting plate I designed. As you probably know, the mounting

plate for the ETX 125 is put between the smal tripod-head and

the larger plastic base of the telescope, thus preventing the scope

from shaking. This because the plastic telescope-bottom is not as

stiff as the metal head. By supporting the whole base of the scope,

much shaking is prevented. Some people came with the idea of

extending this mounting-plate to get a kind of shelf, where you can

put some eye-pieces or hang the AutoStar on. At Mike

Weasner's site there are a few listed, also Scopetronix

sells one (under 'Tripods & Mounts' -> 'Tripod adapters').

This

is the mounting plate I designed. As you probably know, the mounting

plate for the ETX 125 is put between the smal tripod-head and

the larger plastic base of the telescope, thus preventing the scope

from shaking. This because the plastic telescope-bottom is not as

stiff as the metal head. By supporting the whole base of the scope,

much shaking is prevented. Some people came with the idea of

extending this mounting-plate to get a kind of shelf, where you can

put some eye-pieces or hang the AutoStar on. At Mike

Weasner's site there are a few listed, also Scopetronix

sells one (under 'Tripods & Mounts' -> 'Tripod adapters').

I would be happy to have one of those but the prices are rather high

for me. Living in Austria, the Dollar-exchange-rate is rather

unfavorable at the moment and the shipping costs are also rather

high. (I had to pay 50% more than the US-prices for my ETX125 here

in Austria!)

So, I decided to make one myself. This is not a difficult thing, the

main trouble is the drilling and cutting of the plate. But since I

work in a battery-plant, we have a large workshop with a few skilled

people......

A co-worker of me did the complete drawing in Autocad. First thing

to do was measuring the original plate, to get the holes at the

right place. All these holes don't have to be very precise, beacuse

the are just used to lead some screws through, or the give place for

the three rubber feet of the telescope. After this, we put on a

rectangle containg for holes for eye-pieces and a hold for the

Autostar. This rectangle is faced north, so the eye-pieces are in

mostly in reach when viewing south, and the telescope-connectors

won't be obstructed. Of course, one can add more holes, but this was

enough for me. These four holes have to be rather exact in size, to

prevent the eyepieces of falling through. The eye-piece-holes are

arranged in a half-circle, to leave more place in the corner, making

room for a level-bubble or a compass.

This is the stage the project is in at the moment (5. Nov 2000).

Since it didn't cost me a dime until now, I can't expect to be ready

within a week or so. When it's ready, I'll update this site...

Now there is the question of material. The original plate is made

from 3mm thick steel, another commercially available product from

6mm Aluminium. The thickness is not very important, eventually it

could be made out of wood. Important is to make it real stiff, thus

preventing shaking. Another possibility is my design cut out of

plastic or cardboard, and used in addition to the original plate,

simply by putting the two plates on top of each other. Also, with a

thicker plate (wood or aluminium), be sure that the two mounting

screws are long enough to hold the telescope secure on the tripod.

Next thing will be the cutting. Another co-worker took the drawing

with measurements we made, and tries to ask a friend of him to cut

the plate in 3mm steel with an automatic laser-cutting machine,

using the electronic Autocad data. When that doesn't work, yet

another co-worker already promised me that he can do it during two

or three weeks, using some spare time. Isn't it nice to have some

friends? 8-)

When my plate is ready, I will put the drawing on this website, so

everyone can use it. You may then alter my design, as long as you

don't use it commercially. So producing one or two from this design

is okay, but producing and selling not. See it as a kind of

open-source. Remember, producing one at a commercial workshop is

rather expensive. When you can't produce one by yourself (or your

company 8-) buying at Scopetronix

or other shops is cheaper and easier. They will be better looking

also....

10.dec.

2000: I recieved my plate a few days ago. The cutting was done

with a wire-cutter, programmed by hand, so the AutoCad-file wasn't

used. The cut is very sharp and exact, it looks very good. As you

see in the picture, the plate isn't finished yet, this is what the

raw aluminium looks like. There are even the felt-liner-lines where

the operator made a quick sketch on the plate.... After a quick test

in my living room, I discovered I put the holes for the eyepieces to

close to the scope, so my standard 26mm won't fit in the middle two

holes. I didn't count for the sloping EXT-base, so larger eyepieces

like my 26mm Plössl won't fit. The holes can only be used by small

eyepieces, but I haven't got any (yet), so I can't test it. The

holes are very exactly cut, and with the thickness of 6mm aluminium,

it is impossible to put them tilted in the holes. Bummer. So much

for not trying a paper-cut prototype... 8-(

10.dec.

2000: I recieved my plate a few days ago. The cutting was done

with a wire-cutter, programmed by hand, so the AutoCad-file wasn't

used. The cut is very sharp and exact, it looks very good. As you

see in the picture, the plate isn't finished yet, this is what the

raw aluminium looks like. There are even the felt-liner-lines where

the operator made a quick sketch on the plate.... After a quick test

in my living room, I discovered I put the holes for the eyepieces to

close to the scope, so my standard 26mm won't fit in the middle two

holes. I didn't count for the sloping EXT-base, so larger eyepieces

like my 26mm Plössl won't fit. The holes can only be used by small

eyepieces, but I haven't got any (yet), so I can't test it. The

holes are very exactly cut, and with the thickness of 6mm aluminium,

it is impossible to put them tilted in the holes. Bummer. So much

for not trying a paper-cut prototype... 8-(

I have to bevel the edges, and then think of a nice finish for the

surface. Maybe a sandblasting (we have a sand-blasting machine at

the company) or just a painted surface. I haven't decided yet. But

when I bevel the edges, I'll try to make the inner two

eyepiece-holes also somewhat bigger in one direction, so I can put

in the eyepieces tilted.

Unfortunately, this time is rather busy for me, so I guess I won't

be able to do something until somewhere in january. But when I look

at the sky (the thing that have to lie behind that #&%$* fog), I

guess there will be clouds for the next three months... 8-(

25.may.

2003: It is a long time, but finally I made it to make the

update and tell about the finished plate. The plate as I finally

recieved it looked like the picture on the left. It has a nice

brushed aluminium look, mainly because it is brushed

aluminium.

Unfortunately, I miscalculated the design, and put the holes for the

eyepieces to close to the telescope. So I can only use

When there are questions, don't hesitate to contact me.